Feather Grinding

Machine

by Thomas Morrell

I have built a few feather grinding jigs as shown on Dean Torges web

site. Since using them with a drill press set up, I thought I would try

setting up a seperate machine or jig to do the job. The drill press I

have is a smaller one and I am pretty sure I have it at the highest rpm

setting possible. I got a different sanding drum that can be slid on to

a 1/2" shaft. I then mounted it on a 1/6th HP electric motor and

mounted the motor in a vertical position on a 2x6. Since a guide could

not be mounted on this type of sanding drum, I simply used the guide

rail and spacer guide rail which do the job just fine. With the electic

motor spinning at around 1800 rpms it makes a really quick job of

grinding the feathers and also leaves the quill super smooth.

Since building this, I have added a switch to turn it on and off, a

receptacle in the back that a shop vac or clamp light can be plugged

into. In the near future I plan on installing some pipe that a shop vac

tube can fit right into for an exhaust system. I have also built 2

feather grinding clamps that are exactly the same in case you have help

grinding feathers. That way one person can be loading a jig while the

other is grinding. Below are 3 pictures of the grinding machine.

Thanks to Dean Torges for getting I and others started on this fun and

productive project.

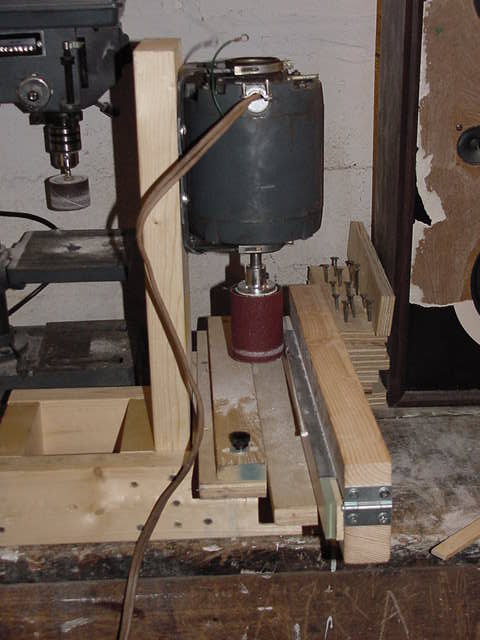

Picture

1: This picture shows grinding the width of the quill.

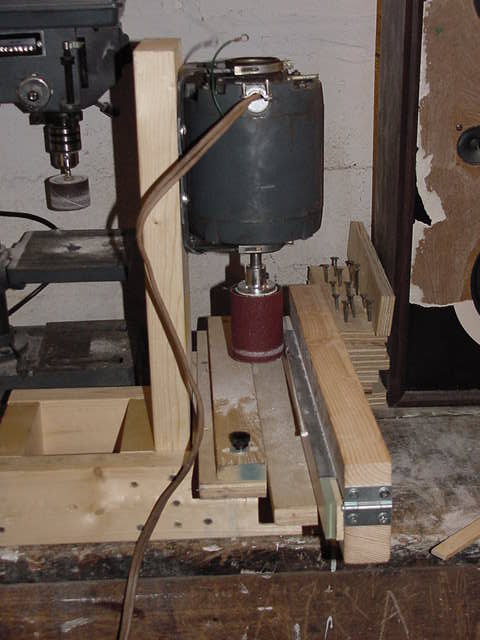

Picture

2: With a spacer guide you can now grind the thickness of the quill

Picture

3: Here all the cords are tucked away, switch added and the

clamps stored on the side.

Questions or comments?

email: Card13@aol.com